Department of Bioengineering, Integral University, Lucknow-226026, Uttar Pradesh, India

Bioplastics are a type of plastic which are natural and renewable. These are made from raw materials such as sugarcane, corn starch, wood, wastepaper, fats, bacteria, algae. Bioplastics are eco-friendly as they can decompose back into carbon dioxide. Reduction of greenhouse gases through reduced carbon footprint occurs by the usage of renewable resources. In contrast to petrochemical plastics, bioplastics production is around 80% which is less than carbon dioxide. Bioplastics have been used as attractive materials for biomedical applications due to their physicochemical, biological, and degradation properties. Due to the widespread use of bioplastics, they are essential materials. Biowaste products should be designed correctly for the benefit of the environment and the utilization of these products. In composting and an anaerobic digestion infrastructure, a part of biorefineries, technology is beneficial. Enhanced production of plastics across the globe has been added more waste pollution. Recycling plastic waste is one solution to the increased plastic pollution, but it alone is not the only one. Decreased usage of fossil-based plastics is vital in the aspect of sustainability. This study aims to review the recent advances of bioplastics and their possible implications for controlling and managing plastic pollution.

Keywords:Bioplastic, Food waste, Microbes, Biodegradable, Waste management

The plastics are typically organic polymers of high molecular mass, but they often contain other substances. They are usually synthetic, most derived from petrochemicals, but many are partially natural. The dumping of waste material like plastic, polythene bags, bottles, and other housewares generated in vast quantities causes environmental hazards. Discharge of plastics in water bodies can lead to severe water contamination affecting the food chain of marine life, thereby causing long-term carcinogenic effects due to the release of diethylhexyl phthalate, lead, mercury, and cadmium. Microplastic debris which floats on the sea surface also contaminates the oceans. To overcome plastic waste and pollution on our planet, we must reduce plastic consumption and raise awareness about plastic recycling. The crucial need to minimize the consumption of plastics has led to the broad expansion of bio-based plastics produced from renewable sources.[1]-[3] About 25.8 million tons of plastic are generated annually, 30% are recycled, and 40% are carbonized. Plastics such as polyethylene terephthalate (PET), polystyrene (PS), polyethylene (PE), Polypropylene (PP) are petrochemically derived, but there is a current demand for plastics used by renewable resources. Bioplastics are essential and requisite materials for substantial and current living. They are also vital for the upcoming generations due to their vast growth and need to be preserved. Bioplastics are biodegradable, and so they can decay with the help of microorganisms in the environment into compounds like carbon dioxide, biomass under aerobic conditions, and methane under anaerobic conditions. Non-biodegradable bioplastics are durable. The intensity of bioplastics being biodegradable is influenced by temperature, polymer stability, and available oxygen content. In emerging economies like India, Brazil, and China, there has been an increased demand for biodegradable polymers. Polyhydroxy and polylactic acid (PLA) is considered the main contributor to the growth of biobased biodegradable plastics, followed by starch known to have the highest share in biodegradable plastic production. The total percentage of bio-based bioplastics is around 2.11 million tons, out of which the PHA has a market share of 1.2%, whereas PLA has that of 13.90%. It is expected that there could be a 6.3-fold increase in the global production of PHA, i.e., from 25.32 tons in 2019 to 159.70 tons by 2024. In PLA, there could be a rise of 8% increased production 293.29 tons in 2019 to 317.00 in 2024.[4]-[17] Maurice Lemoigne, a French chemist, and bacteriologist discovered the Gram-positive bacterium Bacillus megaterium producing intracellular polyester and polyhydroxybutyrate (PHB) while working at the Lille branch of the Pasteur Institute in 1926. Nowadays, around 100 PHAs have been discovered from a variety of microorganisms. The chemists and biologists only began to consider petroleum-based plastics as a gross waste product problem around the 1980s. After that, an intensive search began to look for new ways to make them degrade in municipal and industrial waste facilities. This experiment led to the invention that some genetically altered microorganisms and chemical compounds could help to accelerate the breakdown of petroleum-based plastics to a limited extent. In the upcoming years, these biodegradable polymers can replace conventional polymeric goods in packaging applications. Though it is crucial to characterize the biopolymers permeability to aroma and flavor compounds, little work has been done. Data suggests a limited supply of cost-effective, consumer, and environmentally friendly sustainable plastic alternatives as they are in huge demand.[18]-[30]

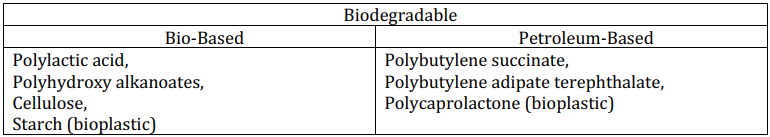

As per the European bioplastics Organization (EBO), a material is called bioplastic if it is either bio-based, biodegradable, or features both properties. The term bio-based is defined as the materials or products entirely or partially acquired from renewable resources. It is why petrochemical resin, typical in standard plastic, is replaced by vegetable or animal polymers, and the compounds like glass or carbon fiber or talc are replaced by natural fibers (wood fiber, hemp, flax, sisal, jute). On the other hand, the term biodegradable refers to the material that can undergo degradation by biological processes at the time of composting to yield CO2, inorganic materials, biomass, water, and other compounds without producing any toxic chemicals or wastes. These materials are made up of different compounds describe above about biodegradable and non-biodegradable bioplastics listed in Table 1.[31]-[41]

Table 1: Types of bioplastics based on biodegradability and bio-based content

Due to the environmental implications of non-biodegradable plastics, significant strides have been taken in the past few years. The best alternative to this is biodegradable plastics as they are environment friendly, with excellent reusable potency that can be produced from natural sources, including waste materials, methane, and other carbon sources. Even though biodegradable plastics are eco-friendly, they risk emitting methane under anaerobic conditions in landfills. Biodegradable plastics produced by methanotrophs are used for landfill methane.[42] The morphology of bio-based material, investigated by scanning electron microscopy, showed a uniform and compact surface structure. 2D X-ray Diffraction analysis reveals that bioplastic is essentially amorphous. Mass loss test noted that it is wholly decomposed after being embedded in soil for 105 days.[43] A few examples of bioplastics are described below.

PHA: PHA is manufacture with the help of microbial fermentation processes, and it was extracted by microbial cells. The diversity in their monomeric compositions causes variations in their physical properties, and thus, it introduces a wide variety of applications.[44]

PLA: PLA is transparent and is manufacture by corn and dextrose. PLA has a similar character as that of petrochemical-based plastics, and it can be manufacture by a similar method as that of conventional plastic.

PHB: The production of poly-3-hydroxybutyrate certain bacteria producing glucose and corn starch is used. PHB has the same characteristic as that of plastic polypropylene. PHB has a higher melting point than 130 degrees C, is biodegradable, and can be processed into transparent films. PHB is used for packaging purposes in South American industries.[45]

PA11: Derivation of PA11 is derived from natural oils and has the triad name Rilsan v, manufactured by Arkema. PA11 is non-biodegradable and shows similar properties to PA12. Automatic fuel lines, pneumatic airbrake tubing, flexible oil and gas pipes are some of the applications of PA11. The manufacturer of polyamide 410 (PLA410) is BSM, and its trade name is EcoPaXX.

PHU: The reaction between polyamines and cyclic carbonates produces polyhydroxyurethanes. They have biodegradables and isocyanate. Cross-linked polyhydroxyurethanes can also be recycled.

Starch: The most widely used bioplastic is thermoplastic starch, consisting of about 50% of the bioplastic market. Due to the absorption of humidity by pure starch is used to produce drug capsules by the pharmaceutical sector. Pure starch-based bioplastic is brittle. Glycerol is added to starch as a plasticizer, and its tensile properties are suitable for packing materials.[46]

Cellulose: There are two types of cellulosic plastic which are organic cellulose esters and regenerated cellulose. At present, around 20% of the global total chemical-grade pulp is utilized to produce organic cellulose ester. Cellulose regenerates manufactured from cellulose by dissolving by chemicals and then newly restructured in fibers or film. More than 60% of the global total chemical-grade pulp is used to form cellulose regenerates.[35]

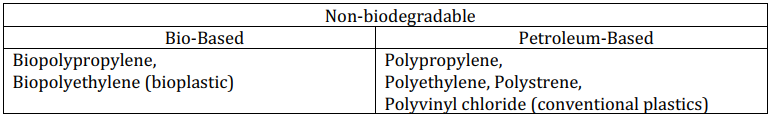

GM bioplastics: GM crops are being used to obtain genetically modified bioplastics. In the upcoming generation, the plant factory model might use GM crops of GM Bactria to optimize the efficiency of GM bioplastics.[47] Bioplastic production capacity global distribution by the material is shown in Figure 1.

Figure 1: Production capacity and material-wise distribution of bioplastics. The blue and black shows the year 2016 and 2021 respectively.[48]

It is predicted that the bioplastics packaging market will grow at a considerable rate from 2021 to 2024. Biodegradable, compostable, and degradable where the aspects examine by the bioplastic for agribusiness. The biodegradable bioplastics are expected to grow at the fastest rate during the forecast period. The Global Bioplastics for Agribusiness Market is expected to grow from USD 1,673.85 Million in 2020 to USD 3,411.10 Million by the end of 2025. The rise of biopolymer capacity and manufacture displace healthy growth in demand from our society. The global bioplastic utensils market declares information based on current market trends, restraints, and drivers.

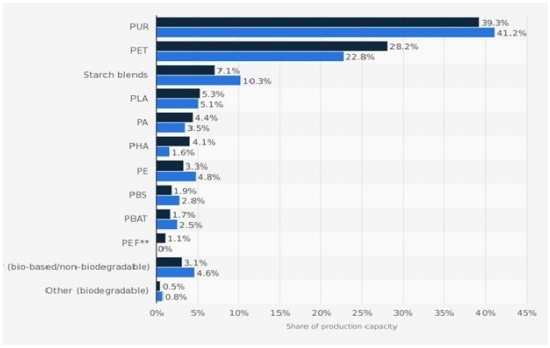

Figure 2: Worldwide production capacity of bioplastics by type.[54],[55]

Bioplastics market size worldwide was estimated at over 1220 kilotons in 2020 and projected to be increased the CAGR (Compound Annual Growth Rate) by over 16% during the forecast period (2021- 2026). In 2020, the market was heavily impacted by the COVID-19. The demand for flexible packaging has increased, accounting >45% for bioplastics due to an upsurge in demand for various usages including personal, healthcare products, pharmaceuticals, food, and beverages packing. According to JEITA (Japan Electronics and Information Technology Industries Association), global electronics products such as laptops, mobiles, and semiconductors, amongst others, and information technology have increased. It is expected to reach USD 3,175 billion by the end of 2021, positively impacting bioplastics’ demand. While there have been struggles for the bioplastics to deliver the same performance as fossil-based plastics, though the technology is increasingly closing the gap, creating highly functional plastics that do not cost the Earth.[49]-[53] Bioplastics production capacity worldwide is shown in Figure 2.

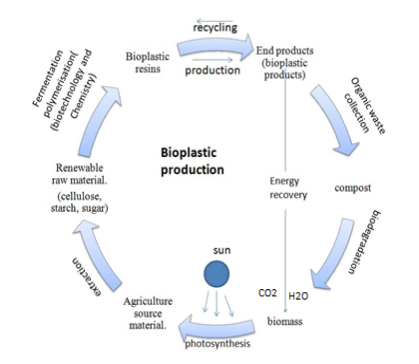

Potential environmental impact is attributed to the life cycle of products or survives, and it is a standard methodology for life cycle assessments (LCA). LCA can acknowledge the materials or products on the environment, optimal use of resources, and the impact of different processes. For example, conventional and biodegradable plastic, use of plastic waste, or natural fiber-based bags and textiles can be determined by LCA. Treatment of PLA waste in a Municipal Solid Waste Incinerator (MSWI) plant is compared to the recently developed recycling processes such as mechanical recycling, chemical recovery, and solvent water recycling. One way to specify problematic environmental hotspots in the manufacture of significant biochemical, which here also are chemicals produced from renewable biomass with microbial fermentation. LCA shows some hotspots for enhancing biomass input, even if the biochemical does not arrive in an oil-derived version.[56]-[61] Bioplastic production and its life cycle are shown in Figure 3.

Figure 3:Bioplastic production and its life cycle.[58]

When the partial or complete breakdown of a polymer occurs due to microbial activity into carbon, hydrogen, oxygen, hydrolysis, photodegradation, microbial action (enzyme secretion), and within-cell processes, the biodegradation process is temperature-dependent. It sometimes requires conditions like industrial composting units with a prolonged temperature of above 50°C to be wholly broken down. Biodegradable plastic is usually created from natural by-products and is controlled by temperature and humidity in industrial environments. Plastic biodegradable and compostable are mostly called bioplastic, and they are generally made from natural resources, such as bamboo or sugarcane, instead of fossil fuels. The compostability of bioplastics needs to be confirmed if the bioplastics are to be pretty and effectively biodegradable to make sure they can be handled in industrial composting plants.[62]-[64] The degradation of bioplastics in the soil environment is shown in Table 2.

Table 2: Degradation of bioplastics in the soil environment.

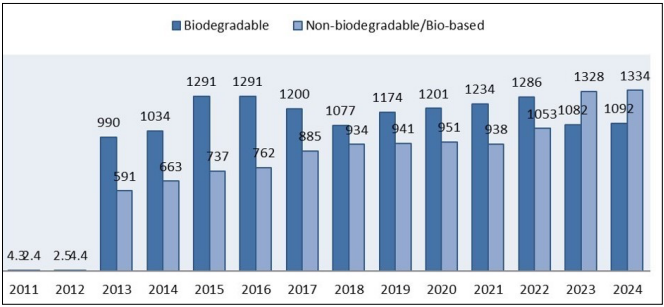

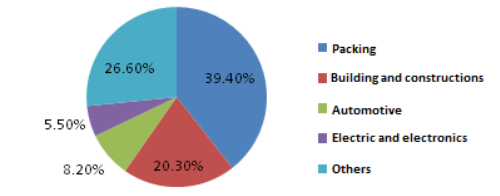

The circular use for biodegradable plastics and the creation of a solid secondary raw material market, and an opportunity for renewable energy generation all come under organic recycling. Life cycle assessment (LCA) helps to reduce contamination of mechanical recycling streams by facilitating separate collection of bio-waste and diverting organic waste from other recycling streams. Investments into sound waste management infrastructure and comprehensive projects to increase the consumer’s knowledge about correct disposal must be considered. By following the above methods, recycling can become more efficient, contamination can be limited, and the solid secondary raw material market in a circular economy can thrive. Commonly, most household packaging is already recycled today, more than half of which (56%) are made from materials (around 20 years ago, it was only 3%).[65], [66] The application of bioplastics in different areas are shown in Figure 4.

Figure 4. Bioplastics from renewable biomass and their applications in different sectors.[63]

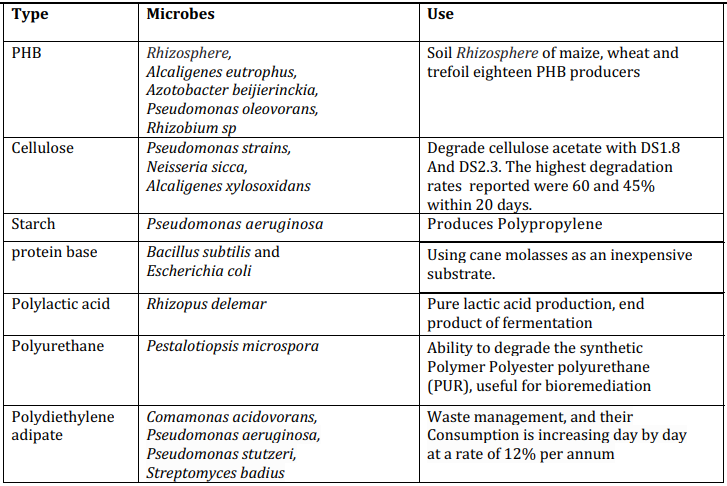

Bioplastics can degrade naturally and entirely to carbon dioxide and water with the help of the enzymatic reaction of the microorganisms. Data suggests that 313 microbes were isolated from 52 soil samples from the Arctic region and out of these, 121 (38.66%) showed biodegradation activity. The ability of precise zone formation on emulsified poly (butylene succinate-co-adipose) (PBSA) was observed for 116 microorganisms (95.87%), on poly (butylene succinate) (PBS) for 73 microorganisms (60.33%), and poly (ɛ-caprolactone) (PCL) for 102 microorganisms (84.3%). Nowadays, out of approximately 300 million tons globally, bioplastics constitute only 1 percent of produce annually.[67]-[69] Table 3 shows the microbes used in the biodegradation of bioplastics.

Table 3: Types of bioplastics and the microbes used in biodegradation.[70]-[76].

The environment-friendly rebound to plastic is bioplastics, which can quickly degrade through the enzymatic action of microorganisms. Examples of environmental effects are summarized as follows. Sustainability: Plastics can be made sustainable by simply adding less chemical diversity to them. Due to the micro partials of the plastic scattering can clog up the sewage drains and thus cause water and sewage problems. Organisms can swallow micro partials mistaking food, and it can cause death and injury to them. It can be stopped by controlling our actions by not littering our surroundings. Worldwide conservation and environmental organization: Many organizations contribute to cleaning up the ecosystem, like Ocean Conservancy (international coastal clean-up), UNEP (United Nations environment programmed), Californians against waste, National wildlife federation, Rainforest Action Network, Tree people, WWF global.[77]-[79] Recycling: The global average of plastic waste recycling is around 14-18%, and it is lower than expected in some countries. In Europe, recycling recently overtook landfilling in post-consumer waste treatment in 2016 with a recycling rate of 31.3% and a landfilling rate of 27.3%.[80] There are four main recycling mechanisms for thermoplastic, including closed-loop, mechanical, chemical, and quaternary.[81]-[84]

According to FAO, around 1.3 billion tons of food is lost or wasted every year globally. In the UK, 15 million tons of food were wasted annually. It is estimated that in Malaysia, around a 6.7million tons of FW are generated annually in 2020. About 567- 726 million tons of FW have been generated annually in the USA. The government of France has introduced a policy for stimulating valorization of FW through the recovery of energy (e.g., biogas) and value-added materials (e.g., a bioplastic) with a punitive law amid an FW epidemic implementation of this policy was estimated to save 88 million tons of FW per year with a corresponding cost of USD 167 billion. Most parts of FW can be recycled (if separated), and recycling will help reduce the overall expenditures on waste management. Although many studies have reported the simultaneous conversion of FW into energy and bioplastics, most emphasized bioplastic production processes, new bacterial/archaeal species use in the fermentation process, and their operating conditions. According to the Ceresin in Constance, Germany, the world market for bioplastic in 2021 will be 3times larger than in 2014, generating a total of USD 5.8 billion in revenue.[85]-[87] The disposal system of bioplastic should be technologically realistic and practical without risking the existing recycling system. Four main food waste valorization techniques have been adopted as a generation to biofuels, Recovery, and extraction of value e-added compounds, Production of bio-adsorbents for wastewater treatment, and Production of biomaterials.

The King Abdullah University Hospital in Jordan produced tenfold higher medical waste (~650 kg per day, when considering an occupation of 95 COVID-19 patients) than the average generation rate during the regular operational day of the hospital. According to Central Pollution Control Board, India generated over 18,000 tons of COVID-19 related bio-medical waste. An extreme increase in medical waste was also disclosed in other parts of the world, as in Catalonia, Spain, and China, with an increment of 350% and 370%, respectively. Wuhan inhabitants in China (~11 M) produced 200 tons of medical waste on a single day (on February 24, 2020). It is four times higher than incinerated by the city’s only dedicated facility, forcing authorities to deploy mobile treatment facilities. For example, around 129 billion facemask and 65 billion gloves would be essential to protect citizens worldwide.[88]-[90]

This review paper includes the bioplastic, their type, degradability, standards, advantages, and disadvantages. There is an urgent need to standardize all details. A new guide and standard should be developed just for bioplastics’ production, uses, and waste management worldwide. Also, labeling legislation may be improved based on a product’s raw material usage, energy consumption, emissions from manufacture and use. Based on the advantages of bioplastics, there are certainly an abundant amount of materials and resources to create and find more uses for bioplastic. Based on the disadvantages of bioplastics, several parameters must be considered for sustainability, including the raw materials from which the bioplastic is generated, the energy consumed during bioplastic conversion, and its life cycle assessment analysis from production to ultimate disposal or recycle, and other several parameters.

The authors declare that there are no conflicts of interest relevant to this article.

References

- 1.Narancic T, Cerrone F, Beagan N, O’Connor KE. Recent Advances in Bioplastics: Application and Biodegradation. Polymers (Basel). 2020;12(4):920-57. [Google Scholar] [PubMed]

- 2.Karan H, Funk C, Grabert M, Oey M, Hankamer B. Green Bioplastics as Part of a Circular Bioeconomy. Trends Plant Sci. 2019;24(3):237-49. [Google Scholar] [PubMed]

- 3.Báreková A, Demovičová M, Tátošová L, Danišová L, Medlenová E, Hlaváčiková S. Decomposition of SingleUse Products Made of Bioplastic under Real Conditions of Urban Composting Facility. J Ecol Eng. 2021;22(4):265–72. [Google Scholar] [PubMed]

- 4.Marichelvam, Jawaid, Asim. Corn and Rice Starch-Based Bio-Plastics as Alternative Packaging Materials. Fibers. 2019;7(4):32. [Google Scholar] [PubMed]

- 5.Smith MKM, Paleri DM, Abdelwahab M, Mielewski DF, Misra M, Mohanty AK. Sustainable composites from poly(3-hydroxybutyrate) (PHB) bioplastic and agave natural fibre. Green Chem. 2020;22(12):3906–16. [Google Scholar] [PubMed]

- 6.Escobar N, Britz W. Metrics on the sustainability of region-specific bioplastics production, considering global land use change effects. Resour Conserv Recycl. 2021;167:105345. [Google Scholar] [PubMed]

- 7.Chander M. Microbial Production of Biodegradable Plastics from Agricultural Waste. Int J Res Anal Rev. 2019;6(2). 2348-1269. [Google Scholar] [PubMed]

- 8.Calero M, Godoy V, Quesada L, Martín-Lara MÁ. Green strategies for microplastics reduction. Curr Opin Green Sustain Chem. 2021;28:100442. [Google Scholar] [PubMed]

- 9.Song JH, Murphy RJ, Narayan R, Davies GBH. Biodegradable and compostable alternatives to conventional plastics. Philos Trans R Soc B Biol Sci. 2009;364(1526):2127–39. [Google Scholar] [PubMed]

- 10.Iles A, Martin AN. Expanding bioplastics production: sustainable business innovation in the chemical industry. J Clean Prod. 2013;45:38–49. [Google Scholar] [PubMed]

- 11.Nandakumar A, Chuah J-A, Sudesh K. Bioplastics: A boon or bane? Renew Sustain Energy Rev. 2021;147:111237. [Google Scholar] [PubMed]

- 12.Kakadellis S, Harris ZM. Don’t scrap the waste: The need for broader system boundaries in bioplastic food packaging life-cycle assessment – A critical review. J Clean Prod. 2020;274:122831. [Google Scholar] [PubMed]

- 13.Alonso-González M, Felix M, Guerrero A, Romero A. Effects of Mould Temperature on Rice Bran-Based Bioplastics Obtained by Injection Moulding. Polymers (Basel). 2021; 13(3):398. [Google Scholar] [PubMed]

- 14.Confente I, Scarpi D, Russo I. Marketing a new generation of bio-plastics products for a circular economy: The role of green self-identity, self-congruity, and perceived value. J Bus Res. 2020;112:431–9. [Google Scholar] [PubMed]

- 15.Di Bartolo A, Infurna G, Dintcheva NT. A Review of Bioplastics and Their Adoption in the Circular Economy. Polymers (Basel). 2021;13(8):1229. [Google Scholar] [PubMed]

- 16.Nasir NN, Othman SA. Effect of Radiation Treatment on Starch Bioplastic- A Review. Int J Adv Life Sci Res. 2019;02(04):1–7. [Google Scholar] [PubMed]

- 17.Kale G, Kijchavengkul T, Auras R, Rubino M, Selke SE, Singh SP. Compostability of Bioplastic Packaging Materials: An Overview. Macromol Biosci. 2007;7(3):255–77. [Google Scholar] [PubMed]

- 18.Battista F, Frison N, Bolzonella D. Can bioplastics be treated in conventional anaerobic digesters for food waste treatment? Environ Technol Innov. 2021;22:101393. [Google Scholar] [PubMed]

- 19.Waldrop MM. Core Concept: Bioplastics offer carbon-cutting advantages but are no panacea. Proc Natl Acad Sci. 2021;118(12):e2103183118. [Google Scholar] [PubMed]

- 20.DiGregorio BE. Biobased Performance Bioplastic: Mirel. Chem Biol. 2009;16(1):1–2. [Google Scholar] [PubMed]

- 21.Acquavia M, Pascale R, Martelli G, Bondoni M, Bianco G. Natural Polymeric Materials: A Solution to Plastic Pollution from the Agro-Food Sector. Polymers (Basel). 2021;13(1):158. [Google Scholar] [PubMed]

- 22.Yong JJJY, Chew KW, Khoo KS, Show PL, Chang J-S. Prospects and development of algal-bacterial biotechnology in environmental management and protection. Biotechnol Adv. 2021;47:107684. [Google Scholar] [PubMed]

- 23.Yaradoddi JS, Banapurmath NR, Ganachari S V., Soudagar MEM, Mubarak NM, Hallad S, et al. Biodegradable carboxymethyl cellulose based material for sustainable packaging application. Sci Rep. 2020;10(1):21960. [Google Scholar] [PubMed]

- 24.Gadhave R V., Das A, Mahanwar PA, Gadekar PT. Starch Based Bio-Plastics: The Future of Sustainable Packaging. Open J Polym Chem. 2018;08(02):21–33. [Google Scholar] [PubMed]

- 25.Muhammad Shamsuddin I. Bioplastics as Better Alternative to Petroplastics and Their Role in National Sustainability: A Review. Adv Biosci Bioeng. 2017;5(4):63. [Google Scholar] [PubMed]

- 26.Patni N, Shah P, Agarwal S, Singhal P. Alternate Strategies for Conversion of Waste Plastic to Fuels. ISRN Renew Energy. 2013;2013:1–7. [Google Scholar] [PubMed]

- 27.Degli Esposti M, Morselli D, Fava F, Bertin L, Cavani F, Viaggi D, et al. The role of biotechnology in the transition from plastics to bioplastics: an opportunity to reconnect global growth with sustainability. DazMoreno I, editor. FEBS Open Bio. 2021;11(4):967–83. [Google Scholar] [PubMed]

- 28.Jariyasakoolroj P, Leelaphiwat P, Harnkarnsujarit N. Advances in research and development of bioplastic for food packaging. J Sci Food Agric. 2020;100(14):5032–45. [Google Scholar] [PubMed]

- 29.Maragkaki A, Sampathianakis I, Katrini K, Michalodimitraki E, Gryparis C, Raptis V, et al. Bio-waste to Bioplastic (B2B): Production of Compostable Bio-Plastics from Food Waste. Proceedings. 2020;30(1):47. [Google Scholar] [PubMed]

- 30.Bhatia SK, Otari S V., Jeon J-M, Gurav R, Choi Y-K, Bhatia RK, et al. Biowaste-to-bioplastic (polyhydroxyalkanoates): Conversion technologies, strategies, challenges, and perspective. Bioresour Technol. 2021;326:124733. [Google Scholar] [PubMed]

- 31.Aradoddi J, Patil V, Ganachari S, Banapurmath N, Hunashyal A, Shettar A, et al. Biodegradable Plastic Production from Fruit Waste Material and Its Sustainable Use for Green Applications. Int J Pharm Res Allied Sci. 2016;5(4):56-66. [Google Scholar] [PubMed]

- 32.Sharma B, Jain P. Deciphering the advances in bioaugmentation of plastic wastes. J Clean Prod. 2020;275:123241. [Google Scholar] [PubMed]

- 33.Jõgi K, Bhat R. Valorization of food processing wastes and by-products for bioplastic production. Sustain Chem Pharm. 2020;18:100326. [Google Scholar] [PubMed]

- 34.Bishop G, Styles D, Lens PNL. Environmental performance comparison of bioplastics and petrochemical plastics: A review of life cycle assessment (LCA) methodological decisions. Resour Conserv Recycl. 2021; 168:105451. [Google Scholar] [PubMed]

- 35.Selvamurugan Muthusamy M, Pramasivam S. Bioplastics – An Eco-friendly Alternative to Petrochemical Plastics. Curr World Environ. 2019;14(1):49–59. [Google Scholar] [PubMed]

- 36.Brodin M, Vallejos M, Opedal MT, Area MC, Chinga-Carrasco G. Lignocellulosics as sustainable resources for production of bioplastics – A review. J Clean Prod. 2017;162:646–64. [Google Scholar] [PubMed]

- 37.Chan JX, Wong JF, Hassan A, Zakaria Z. Bioplastics from agricultural waste. In: Biopolymers and Biocomposites from Agro-Waste for Packaging Applications. J Polym Environ. 2016;19(1):141–69. [Google Scholar] [PubMed]

- 38.Philp JC, Bartsev A, Ritchie RJ, Baucher M-A, Guy K. Bioplastics science from a policy vantage point. N Biotechnol. 2013;30(6):635–46. [Google Scholar] [PubMed]

- 39.Issifu I, Sumaila UR. A Review of the Production, Recycling and Management of Marine Plastic Pollution. J Mar Sci Eng. 2020;8(11):945. [Google Scholar] [PubMed]

- 40.Kumar Gupta G, De S, Franco A, Balu A, Luque R. Sustainable Biomaterials: Current Trends, Challenges and Applications. Molecules. 2015;21(1):48. [Google Scholar] [PubMed]

- 41.Ilyas RA, Sapuan SM, Ishak MR, Zainudin ES, Atikah MSN. Characterization of Sugar Palm Nanocellulose and Its Potential for Reinforcement with a Starch-Based Composite. In: Sugar Palm Biofibers, Biopolymers, and Biocomposites. First edition. Boca Raton, FL : CRC Press/Taylor & Francis Group, 2018.: CRC Press; 2018. p. 189–220 [Google Scholar] [PubMed]

- 42.Chidambarampadmavathy K, Karthikeyan OP, Heimann K. Sustainable bio-plastic production through landfill methane recycling. Renew Sustain Energy Rev. 2017;71:555–62. [Google Scholar] [PubMed]

- 43.Bilo F, Pandini S, Sartore L, Depero LE, Gargiulo G, Bonassi A, et al. A sustainable bioplastic obtained from rice straw. J Clean Prod. 2018;200:357–68. [Google Scholar] [PubMed]

- 44.Meereboer KW, Misra M, Mohanty AK. Review of recent advances in the biodegradability of polyhydroxyalkanoate (PHA) bioplastics and their composites. Green Chem. 2020;22(17):5519–58. [Google Scholar] [PubMed]

- 45.Rai P, Mehrotra S, Priya S, Gnansounou E, Sharma SK. Recent advances in the sustainable design and applications of biodegradable polymers. Bioresour Technol. 2021;325:124739. [Google Scholar] [PubMed]

- 46.Srivastava R, Singh R. Bioplastics: requirement for sustainability. Am J Environ Biol. 2020:50–9. [Google Scholar] [PubMed]

- 47.Trivedi P, Hasan A, Akhtar S, Siddiqui MH, Sayeed U, Khan MKA, et al. Role of microbes in degradation of synthetic plastics and manufacture of bioplastics. 2016;8(3):211–6 [Google Scholar] [PubMed]

- 48.Reshmy R, Thomas D, Philip E, Paul SA, Madhavan A, Sindhu R, et al. Bioplastic production from renewable lignocellulosic feedstocks: a review. Rev Environ Sci BioTechnology. 2021;20(1):167–87. [Google Scholar] [PubMed]

- 49.Moshood T, Nawanir G, Mahmud F, Mohamad F, Ahmad M, Abdul Ghani A. Expanding Policy for Biodegradable Plastic Products and Market Dynamics of Bio-Based Plastics: Challenges and Opportunities. Sustainability. 2021;13(11):6170. [Google Scholar] [PubMed]

- 50.Parashar N, Hait S. Plastics in the time of COVID-19 pandemic: Protector or polluter? Sci Total Environ. 2021;759:144274. [Google Scholar] [PubMed]

- 51.Hale RC, Song B. Single-Use Plastics and COVID-19: Scientific Evidence and Environmental Regulations. Environ Sci Technol. 2020 Jun 16;54(12):7034–6. [Google Scholar] [PubMed]

- 52.Bhagwat G, Gray K, Wilson SP, Muniyasamy S, Vincent SGT, Bush R, et al. Benchmarking Bioplastics: A Natural Step Towards a Sustainable Future. J Polym Environ. 2020;28(12):3055–75. [Google Scholar] [PubMed]

- 53.Filho WL, Salvia AL, Bonoli A, Saari UA, Voronova V, Klõga M, et al. An assessment of attitudes towards plastics and bioplastics in Europe. Sci Total Environ. 2021;755:142732. [Google Scholar] [PubMed]

- 54.Thakur S, Chaudhary J, Sharma B, Verma A, Tamulevicius S, Thakur VK. Sustainability of bioplastics: Opportunities and challenges. Curr Opin Green Sustain Chem. 2018;13:68–75. [Google Scholar] [PubMed]

- 55.Godfrey L. Waste Plastic, the Challenge Facing Developing Countries—Ban It, Change It, Collect It? Recycling. 2019;4(1):3. [Google Scholar] [PubMed]

- 56.Kakadellis S, Harris ZM. Don’t scrap the waste: The need for broader system boundaries in bioplastic food packaging life-cycle assessment – A critical review. J Clean Prod. 2020;274:122831. [Google Scholar] [PubMed]

- 57.Maga D, Hiebel M, Thonemann N. Life cycle assessment of recycling options for polylactic acid. Resour Conserv Recycl. 2019;149:86–96. [Google Scholar] [PubMed]

- 58.Monshupanee T, Nimdach P, Incharoensakdi A. Two-stage (photoautotrophy and heterotrophy) cultivation enables efficient production of bioplastic poly-3-hydroxybutyrate in auto-sedimenting cyanobacterium. Sci Rep. 2016;6(1):37121. [Google Scholar] [PubMed]

- 59.Koller M. “Bioplastics from microalgae”—Polyhydroxyalkanoate production by cyanobacteria. In: Handbook of Microalgae-Based Processes and Products. Elsevier; 2020. p. 597–645. [Google Scholar] [PubMed]

- 60.Amin MR, Chowdhury MA, Kowser MA. Characterization and performance analysis of composite bioplastics synthesized using titanium dioxide nanoparticles with corn starch. Heliyon. 2019;5(8):e02009. [Google Scholar] [PubMed]

- 61.Dobrucka R. Bioplastic packaging materials in circular economy. Logforum. 2019 30;15(1):129–37. [Google Scholar] [PubMed]

- 62.Coppola G, Gaudio MT, Lopresto CG, Calabro V, Curcio S, Chakraborty S. Bioplastic from Renewable Biomass: A Facile Solution for a Greener Environment. Earth Syst Environ. 2021;5(2):231–51. [Google Scholar] [PubMed]

- 63.Ismail NA, Mohd Tahir S, Norihan Y, Abdul Wahid MF, Khairuddin NE, Hashim I, et al. Synthesis and Characterization of Biodegradable Starch-Based Bioplastics. Mater Sci Forum. 2016;846:673–8. [Google Scholar] [PubMed]

- 64.Rahman MH, Bhoi PR. An overview of non-biodegradable bioplastics. J Clean Prod. 2021;294:126218. [Google Scholar] [PubMed]

- 65.Davis G, Song JH. Biodegradable packaging based on raw materials from crops and their impact on waste management. Ind Crops Prod. 2006;23(2):147–61. [Google Scholar] [PubMed]

- 66.Sekiguchi T, Sato T, Enoki M, Kanehiro H, Uematsu K, Kato C. Isolation and characterization of biodegradable plastic degrading bacteria from deep-sea environments. JAMSTEC Rep Res Dev. 2011;11:33– 41. [Google Scholar] [PubMed]

- 67.Urbanek AK, Rymowicz W, Strzelecki MC, Kociuba W, Franczak Ł, Mirończuk AM. Isolation and characterization of Arctic microorganisms decomposing bioplastics. AMB Express. 2017;7(1):148. [Google Scholar] [PubMed]

- 68.Shah AA, Kato S, Shintani N, Kamini NR, Nakajima-Kambe T. Microbial degradation of aliphatic and aliphatic-aromatic co-polyesters. Appl Microbiol Biotechnol. 2014;98(8):3437–47. [Google Scholar] [PubMed]

- 69.El-Mohamedy Hawas JM, El-Banna TE-S, Abdelmonteleb Belal EB, El-Aziz AA. Production of Bioplastic from some selected Bacterial strains. Int J Curr Microbiol Appl Sci. 2016;5(1):10–22. [Google Scholar] [PubMed]

- 70.Puls J, Wilson SA, Hölter D. Degradation of Cellulose Acetate-Based Materials: A Review. J Polym Environ. 2011;19(1):152–65. [Google Scholar] [PubMed]

- 71.Khoramnejadian S. Microbial degradation of starch-based polypropylene. J Pure Appl Microbiol. 2013;7(4):2857-286. [Google Scholar] [PubMed]

- 72.Asgher M, Qamar SA, Bilal M, Iqbal HMN. Bio-based active food packaging materials: Sustainable alternative to conventional petrochemical-based packaging materials. Food Res Int. 2020;137:109625. [Google Scholar] [PubMed]

- 73.Sauer M, Porro D, Mattanovich D, Branduardi P. 16 years research on lactic acid production with yeast – ready for the market? Biotechnol Genet Eng Rev. 2010;27(1):229–56. [Google Scholar] [PubMed]

- 74.Russell JR, Huang J, Anand P, Kucera K, Sandoval AG, Dantzler KW, et al. Biodegradation of Polyester Polyurethane by Endophytic Fungi. Appl Environ Microbiol. 2011;77(17):6076–84. [Google Scholar] [PubMed]

- 75.Cottet C, Ramirez-Tapias YA, Delgado JF, de la Osa O, Salvay AG, Peltzer MA. Biobased Materials from Microbial Biomass and Its Derivatives. Materials (Basel). 2020;13(6):1263. [Google Scholar] [PubMed]

- 76.Friedrich D. Mixing fossil- and bio-polymers for internalisation of environmental damage: An evidencebased model-theoretical economic analysis. Ecol Econ. 2021;186:107083. [Google Scholar] [PubMed]

- 77.Rujnić-Sokele M, Pilipović A. Challenges and opportunities of biodegradable plastics: A mini review. Waste Manag Res J a Sustain Circ Econ. 2017;35(2):132–40. [Google Scholar] [PubMed]

- 78.Narancic T, O’Connor KE. Plastic waste as a global challenge: are biodegradable plastics the answer to the plastic waste problem? Microbiology. 2019;165(2):129–37. [Google Scholar] [PubMed]

- 79.Narancic T, Verstichel S, Reddy Chaganti S, Morales-Gamez L, Kenny ST, De Wilde B, et al. Biodegradable Plastic Blends Create New Possibilities for End-of-Life Management of Plastics but They Are Not a Panacea for Plastic Pollution. Environ Sci Technol. 2018;52(18):10441–52. [Google Scholar] [PubMed]

- 80.Hopewell J, Dvorak R, Kosior E. Plastics recycling: challenges and opportunities. Philos Trans R Soc B Biol Sci. 2009;364(1526):2115–26. [Google Scholar] [PubMed]

- 81.Yang J, Ching Y, Chuah C. Applications of Lignocellulosic Fibers and Lignin in Bioplastics: A Review. Polymers (Basel). 2019;11(5):751. [Google Scholar] [PubMed]

- 82.Filiciotto L, Rothenberg G. Biodegradable Plastics: Standards, Policies, and Impacts. ChemSusChem. 2021;14(1):56–72. [Google Scholar] [PubMed]

- 83.Andreeßen C, Steinbüchel A. Recent developments in non-biodegradable biopolymers: Precursors, production processes, and future perspectives. Appl Microbiol Biotechnol. 2019;103(1):143–57. [Google Scholar] [PubMed]

- 84.Ilyas RA, Sapuan SM. Biopolymers and Biocomposites: Chemistry and Technology. Curr Anal Chem. 2020;16(5):500–3. [Google Scholar] [PubMed]

- 85.Chan JX, Wong JF, Hassan A, Zakaria Z. Bioplastics from agricultural waste. In: Biopolymers and Biocomposites from Agro-Waste for Packaging Applications. Elsevier; 2021. p. 141–69. [Google Scholar] [PubMed]

- 86.Patrício Silva AL, Prata JC, Walker TR, Campos D, Duarte AC, Soares AMVM, et al. Rethinking and optimising plastic waste management under COVID-19 pandemic: Policy solutions based on redesign and reduction of single-use plastics and personal protective equipment. Sci Total Environ. 2020;742:140565. [Google Scholar] [PubMed]

- 87.Patrício Silva AL, Prata JC, Walker TR, Duarte AC, Ouyang W, Barcelò D, et al. Increased plastic pollution due to COVID-19 pandemic: Challenges and recommendations. Chem Eng J. 2021;405:126683. [Google Scholar] [PubMed]

- 88.Beckstrom BD, Wilson MH, Crocker M, Quinn JC. Bioplastic feedstock production from microalgae with fuel co-products: A techno-economic and life cycle impact assessment. Algal Res. 2020;46:101769. [Google Scholar] [PubMed]

- 89.Shafqat A, Tahir A, Mahmood A, Tabinda AB, Yasar A, Pugazhendhi A. A review on environmental significance carbon foot prints of starch based bio-plastic: A substitute of conventional plastics. Biocatal Agric Biotechnol. 2020;27:101540. [Google Scholar] [PubMed]

- 90.Rupani PF, Nilashi M, Abumalloh RA, Asadi S, Samad S, Wang S. Coronavirus pandemic (COVID-19) and its natural environmental impacts. Int J Environ Sci Technol. 2020;17(11):4655–66. [Google Scholar] [PubMed]