Department of Bioengineering, King Fahd University of Petroleum and Minerals, Dhahran 34463 6391, Saudi Arabia

Abstract: Biofuels researchers extended to fit the growing fuel requirements and protected regional energy. Because of renewable and no impact on carbon biomass is preferred to replace fossil fuels. 2nd generation biofuels generated from micro-algae and lignocellulosic biomass (3rd generation biofuels) have become an essential raw material for the generation of renewable biofuels. Microalgae are rapidly multiplying microorganisms seen in the water, are the essential raw material for bio-fuel generation for the features like huge growth ratio, yield per area, potency in CO2 capture, and solar energy transformation. Photobioreactors on marginal lands, ponds, and seawater is the best growing area for algae, industries also cultivate the algae. Many methods have been used for the generation of biofuels from algae includes anaerobic digestion, hydrothermal liquefication, supercritical water gasification, and pyrolysis. This review article in brief explains the process of biofuel generation by using microalgae.

Keywords: Microalgae, bio-fuel, anaerobic digestion, pyrolysis, gasification

The long-term sources of bio-fuel are found by the many types of research output includes the emerging one is algae. Many features, qualities, and benefits that have made them attractive include their growth and multiplications. Many researchers are working on the cultivation and use of microalgae in biofuel generation. The microalgae biofuel project includes many procedures starting from the growth of algae, harvesting, dehydration, and generation of oils with project costs for the infrastructure, engineering, installation, and initiation.[1] The microalgae have a wide variety of diversity depending on the range of molecules they can generate like vitamins, long-chain polyunsaturated fatty acids, pigments, and antioxidants. This diversity depends on the applications and market needs in the future. It offers an emerging power for inventions and therefore needs to be studied in depth.[2][3] Despite demanding and increasing interest in microalgae for many years, industrial utilization was found limited, some technological errors should be validated to enhance the yields and increase the economic situation of the area. The culture procedure requires the utilization of many energies in all stages starring from the medium agitation for uniformity and holding the algae in suspension to the extractions that may result in loss of energy equivalence.[4] The thrust area for coming is consequently to identify options to the powerful improvement of all of the stages, to balance the energy of the stages is superb in its entirety. The aid of lowering the motion of cells in the agitation stage would enable a common decrease in energy costs. Thus, if this technological know-how is accurately established, energy production from algae will be of treasured monetary advantage.[5]

There are quite a few feasible patterns of tactics for the transfer of microalgae into biofuel energy. It consists of several physical and chemical pre-treatments that are meant to limit the water material and modify the physical shape of the microalga in a segment that we can effortlessly homogenize.

It takes place, in the lack of air, to radically change the microalgae into biogas by using bacterial degradation. This biogas is a traditional gas that we can store and distribute.[6] The deference of microalgae to these bioenergy transform processes is in contrast with other terrestrial and aquatic biomass sources are the absolute best energy yields mentioned in the research have been hydrogen 1.2, methane 14.4, ethanol 14.8, butanol 6.6. The maximum power energy density found from microalgal biomass in microbial fuel cells has been 980 mW m(-2). Stepwise manufacturing of distinct energy carriers enhances plausible attainable energy yields but additionally enhances the funding and upkeep costs.[6]

For ethanol fermentation and methanogenic digestion microalgal biomass is an assuring raw material for the anaerobic energy transforming method. Timely and required for economic comparisons the scale-up of microalgal biomass, the anaerobic utilization for production of energy carriers, because the reported studies have been based on laboratory-scale experiments.[7]

Many photosynthetic organisms produce biomass for many uses by storing and converting solar energy in an anaerobic process. Production of sustainable energy carriers uses anaerobic conditions by utilizing biomass. Microalgae have many benefits in contrast to plants. Pretreatment strategies, biomass composition, parameters of the digestion process affect the powerful biogas production via anaerobic digestion. The efficiency and sustainability of renewable energy production are enhanced by biogas production and coupled biohydrogen.[8]

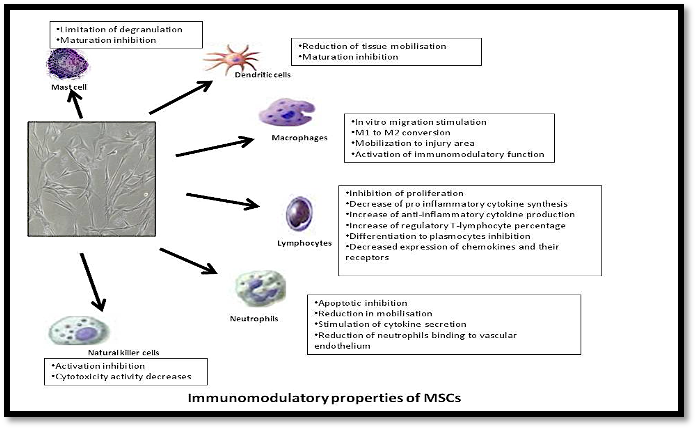

The anaerobic conditions required for the organic compound decomposition and many species of diverse microbes involved in the microbial food chain steadily degrade the complex substance to a mixture of CO2 and CH4.[9]-[11] The concept of microalgal biomass substrate in anaerobic digestion (AD) in the 1950s (Figure. 1), in which a culture mixture of Scenedesmus species and Chlorella species grown in wastewater was utilized. AD process, biogas composition, and stability of many microalgae species were investigated in the literature.[12]-[17]

Strain selection

Various microalgal families were compared, including sea and freshwater strains for biogas generation. A typical feature in mesophilic situations, the CH4 composition of the biogas from the microalgae used to be ~7-13% greater than that from maize silage, the largest substrate in biogas formation. The higher CH4 composition, the usual biogas yields various relying on the algae strains structure of cell wall. Dunaliella salina is an easily biodegradable species either lacks a cell wall or Chlamydomonas reinhardtii cell wall is rich in easily-biodegradable protein.[18]-[20]

Figure 1: The concept of micro-algal-based biogas generation.

Pre-treatments

Biogas products from algae may be enhanced by necessary pre-treatments including solubilization of the cell wall. The important pre-treatment ideas consist of biological mechanical, chemical, thermal methods. Energy utilization or consumption is the main parameter identifying the large-scale use of these methods. Sonication is a type of mechanical pre-treatments that are powerful to solubilize the cell wall, but the energy needs make them noneconomical. Concentrated biomass is required to attain a positive energy balance in thermal pre-treatment to increase biogas production.[21]-[22]

Biological pre-treatments

Various enzymes are needed to degrade the cell wall polymers effectively in biological methods. Protease enzyme pre-treatment of C. vulgaris and S. obliquus increased the CH4 yields 1.53-fold and 1.72-fold respectively. In a similar approach, an enzyme mixture including hemicellulase, cellulase, xylanase, and b-glucanase was powerful in initiating AD of algal biomass. The cost of enzyme production is the limiting factor of the biological pre-treatment methods. Therefore, in situ enzyme generation has been economical. The hydrolytic-acidogenic stage could be separated from the methanogenesis stage in a two-stage AD concept design.[23]-[25]

Converting biomass in a complex method requires physical and chemical structural modifications. Biomass is degraded into small molecules. Unstable and reactive small molecules and may be repolymerized into oily compounds with huge molecular weight distribution. This process has the advantage that wet raw material can be used (energy utilization of water evaporation is inhibited). Temperature between 250 and 350°C, 5 and 20 MPa, and with or without a catalyst is required to operate the liquefaction. In several processes, water is maintained in the subcritical state and hydrogen can be added that gives it special reactive features. In several processes, the water is in a super-critical state. The yield generated is a mixture of gas and oil. Generally, after extraction and evaporation of an organic solvent the bio-oil is produced (e.g. dichloromethane). A liquid phase and solid residue are also produced.[26]-[28]

This process requires high pressure and temperatures to degrade organic compounds into smaller fractions and is the most assuring method to transform wet microalgae raw material to biofuel. To precisely control and observe reaction conditions at high temperature and pressure a microfluidic screening platform is required. Fluorescence enables real-time monitoring and direct monitoring of this method by using in situ observation. Algal slurry at 675 nm (chlorophyll peak) to a post-HTL stream at 510 nm a strong shift fluorescence signature is seen for reaction temperature. Separation from the liquid phase into immiscible droplets and biocrude production is directly seen over the same timescale. The method control and insight process, with a resolution that will direct the concept of large-scale reactors and methods determined by the microfluidic platform.[29] One study reported algal biomass (less than 40 wt% of ash contents) transformed into biocrude oil via HTL (Figure 2).[30]

Figure 2: algal biomass with (less than 40 wt% of ash contents) transformed into biocrude oil via HTL.

It is the chemical decay of a substance under the activity of heat. At temperatures from 350°C to 700°C, biomass is converted into carbon residue, bio-oil, and syngas under low pressure and in the absence of air. Fast heating rates and moderate temperatures and low residence times enhance liquid product yield. The formation of carbonaceous residues occurs at slow pyrolysis, while the formation of bio-oil occurs at fast pyrolysis.[31]-[32]

One study reported the higher aliphatics, lower content of acids and oxygen in the bio-oil, show assurance for generation of high-quality bio-oil from Nannochloropsis by Ni-Ce/Al2O3 catalytic pyrolysis.[33]

Bio-oil is the liquid fraction collected from pyrolysis, the required yield of the process. bio-oil can be used as fuel in turbines and simple boilers for the generation of electricity and heat. The process of pyrolysis is explained and classified into many operation modes (Figure 3).[34]

Figure 3: The process of pyrolysis.

It transforms the carbonaceous materials into hydrogen and carbon monoxide by reaction of the raw material with a controlled quantity of oxygen at very high temperatures (800–1000°C). Gasification methods have two subtypes conventional and supercritical water gasification.[35]-[36]

Conventional gasification

It transforms solid biomass into syngas in an oxygen-lacking environment at a temperature of 800–1000 °C. In contrast to other thermochemical transform methods, the gasification method is more significant due to its potential for large-scale generation of H2 with high energy power.[37] The adjustable H2/CO ratio in the syngas is useful for many ranges of uses, including chemical syntheses such as methanol, ammonia, acetic acid, and power generation. Air, steam, and oxygen are the main gasifying agents used in gasification. The biomass is required to be dried or allowed to a certain moisture content before the gasification process.[38]

Supercritical water gasification

Water behaves like a non-polar solvent beyond the critical point with a decrease in viscosity and thermal conductivity increased diffusivity.[39] Supercritical water acts as an efficient oxidant of more than 600 °C which free radical reactions control which transforms harmful organic substances into stable products.[40] The diagram of supercritical water gasification of algae is illustrated in Figure 4.

Figure 4: supercritical water gasification of algae.

The utilization of extremophilic microalgae and cyanobacteria did clear up many troubles and without a doubt recognized biomass productiveness and harvesting. The two foremost constraints inhibiting microalgae producing bulk chemicals, like biofuels. In response to the global warming, triggered through anthropogenic CO2 emissions, microalgae were once more advised as a carbon impartial method to generate biofuels by using several significant techniques such as anaerobic digestion, hydrothermal liquefication, supercritical water gasification, and pyrolysis.

The author declares that there are no conflicts of interest relevant to this article.

References

- 1.Abo BO, Odey EA, Bakayoko M, Kalakodio L. Microalgae to biofuels production: a review on cultivation, application and renewable energy. Rev Environ Health. 2019 Mar 26; 34(1):91-99. doi: 10.1515/reveh-2018-0052. [Google Scholar] [PubMed]

- 2.Merz CR, Main KL. Microalgae bioproduction – feeds, foods, nutraceuticals, and polymers. Fuels, Chemicals and Materials from the Oceans and Aquatic Sources. New Jersey: Wiley, 2017:83–112. [Google Scholar] [PubMed]

- 3.Scott SA, Davey MP, Dennis JS, Horst I, Howe CJ, Lea-Smith DJ, et al. Biodiesel from algae: challenges and prospects. Curr Opin Biotechnol 2010; 21:277–86. [Google Scholar] [PubMed]

- 4.Collet P, Lardon L, Hélias A, Bricout S, Lombaert-Valot I, Perrier B, et al. Biodiesel from microalgae – Life cycle assessment and recommendations for potential improvements. Renew Energy 2014; 71:525–33. [Google Scholar] [PubMed]

- 5.Cadoret J-P, Bernard O. The production of biofuel lipid with microalgae: promises and challenges. J Soc Biol 2008; 202(3):201–11. [Google Scholar] [PubMed]

- 6.McKendry P. Energy production from biomass (part 2): conversion technologies. Bioresour Technol 2002; 83(1): 55–63. [Google Scholar] [PubMed]

- 7.Lakaniemi AM, Tuovinen OH, Puhakka JA. Anaerobic conversion of microalgal biomass to sustainable energy carriers--a review. Bioresour Technol. 2013 May;135:222-31. [Google Scholar] [PubMed]

- 8.Wirth R, Lakatos G, Böjti T, Maróti G, Bagi Z, Rákhely G, Kovács KL. Anaerobic gaseous biofuel production using microalgal biomass - A review. Anaerobe. 2018 Aug;52:1-8. [Google Scholar] [PubMed]

- 9.Schlüter A, Bekel T, Diaz NN, Dondrup M, Eichenlaub R, Gartemann KH, Krahn I, et al. The metagenome of a biogas-producing microbial community of a production-scale biogas plant fermenter analysed by the 454-pyrosequencing technology. J Biotechnol. 2008 Aug 31;136(1-2):77-90. [Google Scholar] [PubMed]

- 10.Kröber M, Bekel T, Diaz NN, Goesmann A, Jaenicke S, Krause L, Miller D, et al. Phylogenetic characterization of a biogas plant microbial community integrating clone library 16S-rDNA sequences and metagenome sequence data obtained by 454-pyrosequencing. J Biotechnol. 2009 Jun 1;142(1):38-49. [Google Scholar] [PubMed]

- 11.Wirth R, Kovács E, Maróti G, Bagi Z, Rákhely G, Kovács KL. Characterization of a biogas-producing microbial community by short-read next generation DNA sequencing. Biotechnol Biofuels. 2012 Jul 12;5:41. [Google Scholar] [PubMed]

- 12.Golueke CG, Oswald WJ, Gotaas HB. Anaerobic digestion of Algae. Appl Microbiol. 1957 Jan;5(1):47-55. [Google Scholar] [PubMed]

- 13.M. Uziel, Solar Energyfixation and Conversion with Algalbacterial System,California Univ., Berkeley, 1974. [Google Scholar] [PubMed]

- 14.J.D. Keenan, Bioconversion of solar energy to methane, Energy 2 (1977)365-373. [Google Scholar] [PubMed]

- 15.R. Samson, A. Leduy, Biogas production from anaerobic digestion of Spirulina maxima algal biomass, Biotechnol. Bioeng. 24 (1982) 1919-1924. [Google Scholar] [PubMed]

- 16.E.W. Becker, The Production of microalgae as a source of biomass, in:W.A. C^ote (Ed.), Biomass Util, Springer US, Boston, MA, 1983, pp. 205-226. [Google Scholar] [PubMed]

- 17.R. Samson, A. Leduyt, Detailed study of anaerobic digestion of Spirulina maxima algal biomass, Biotechnol. Bioeng. 28 (1986) 1014-1023. [Google Scholar] [PubMed]

- 18.Mussgnug JH, Klassen V, Schlüter A, Kruse O. Microalgae as substrates for fermentative biogas production in a combined biorefinery concept. J Biotechnol. 2010 Oct 1;150(1):51-6. [Google Scholar] [PubMed]

- 19.Miller DH, Lamport DT, Miller M. Hydroxyproline heterooligosaccharides in Chlamydomonas. Science. 1972 May 26;176(4037):918-20. [Google Scholar] [PubMed]

- 20.Klassen V, Blifernez-Klassen O, Hoekzema Y, Mussgnug JH, Kruse O. A novel one-stage cultivation/fermentation strategy for improved biogas production with microalgal biomass. J Biotechnol. 2015 Dec 10;215:44-51. [Google Scholar] [PubMed]

- 21.Passos F, Uggetti E, Carrère H, Ferrer I. Pretreatment of microalgae to improve biogas production: a review. Bioresour Technol. 2014 Nov;172:403-412. [Google Scholar] [PubMed]

- 22.Alzate ME, Muñoz R, Rogalla F, Fdz-Polanco F, Pérez-Elvira SI. Biochemical methane potential of microalgae: influence of substrate to inoculum ratio, biomass concentration and pretreatment. Bioresour Technol. 2012 Nov;123:488-94. [Google Scholar] [PubMed]

- 23.Ding L, Cheng J, Xia A, Jacob A, Voelklein M, Murphy JD. Co-generation of biohydrogen and biomethane through two-stage batch co-fermentation of macro-and micro-algal biomass. Bioresour Technol. 2016 Oct;218:224-31. [Google Scholar] [PubMed]

- 24.Lü F, Ji J, Shao L, He P. Bacterial bioaugmentation for improving methane and hydrogen production from microalgae. Biotechnol Biofuels. 2013 Jul 1;6(1):92. [Google Scholar] [PubMed]

- 25.Demuez M, Mahdy A, Tomás-Pejó E, González-Fernández C, Ballesteros M. Enzymatic cell disruption of microalgae biomass in biorefinery processes. Biotechnol Bioeng. 2015 Oct;112(10):1955-66. [Google Scholar] [PubMed]

- 26.Patil V, Tran KQ, Giselrød HR. Towards sustainable production of biofuels from microalgae. Int J Mol Sci 2008;9(7):1188–95. [Google Scholar] [PubMed]

- 27.Goyal HB, Seal D, Saxena RC. Bio-fuels from thermochemical conversion of renewable resources: a review. Renew Sustain Energy Rev 2008;12(2):504–17. [Google Scholar] [PubMed]

- 28.Dote Y, Sawayama S, Inoue S, Minowa T, Yokoyama S. Recovery of liquid fuel from hydrocarbon-rich microalgae by thermochemical liquefaction. Fuel 1994;73(12):1855–7. [Google Scholar] [PubMed]

- 29.Cheng X, Ooms MD, Sinton D. Biomass-to-biocrude on a chip via hydrothermal liquefaction of algae. Lab Chip. 2016 Jan 21;16(2):256-60. [Google Scholar] [PubMed]

- 30.Tian C, Liu Z, Zhang Y, Li B, Cao W, Lu H, Duan N, Zhang L, Zhang T. Hydrothermal liquefaction of harvested high-ash low-lipid algal biomass from Dianchi Lake: effects of operational parameters and relations of products. Bioresour Technol. 2015 May;184:336-343. [Google Scholar] [PubMed]

- 31.Goyal HB, Seal D, Saxena RC. Bio-fuels from thermochemical conversion of renewable resources: a review. Renew Sustain Energy Rev 2008;12(2):504–17. [Google Scholar] [PubMed]

- 32.Dote Y, Sawayama S, Inoue S, Minowa T, Yokoyama S. Recovery of liquid fuel from hydrocarbon-rich microalgae by thermochemical liquefaction. Fuel 1994;73(12):1855–7. [Google Scholar] [PubMed]

- 33.Aysu T, Sanna A. Nannochloropsis algae pyrolysis with ceria-based catalysts for the production of high-quality bio-oils. Bioresour Technol. 2015 Oct;194:108-16. [Google Scholar] [PubMed]

- 34.J. Fermoso, J.M. Coronado, D.P. Serrano, P. Pizarro. Pyrolysis of microalgae for fuel production, In Woodhead Publishing Series in Energy, Microalgae-Based Biofuels and Bioproducts, Woodhead Publishing, 2017, Pages 259-281. [Google Scholar] [PubMed]

- 35.McKendry P. Energy production from biomass (part 2): conversion technologies. Bioresour Technol. 2002;83(1): 55–63. [Google Scholar] [PubMed]

- 36.Demirbaş A. Biomass resource facilities and biomass conversion processing for fuels and chemicals. Energy Convers Manag. 2001;42(11):1357–78. [Google Scholar] [PubMed]

- 37.Nurdiawati A, Zaini I.N, Irhamna A.R, Sasongko D, Aziz M. Novel configuration of supercritical water gasification and chemical looping for highly-efficient hydrogen production from microalgae. Renew. Sustain. Energy Rev. 2019;112:369-381. [Google Scholar] [PubMed]

- 38.Adnan M, Hossain M. Integrated drying and gasification of wet microalgae biomass to produce H2 rich syngas – a thermodynamic approach by considering in-situ energy supply. Int. J. Hydrog. Energy. 2019;44:10361-10373. [Google Scholar] [PubMed]

- 39.Caputo G, Dispenza M, Rubio P, Scargiali F. Supercritical water gasification of microalgae and their constituents in a continuous reactor. J. Supercrit. Fluids. 2016;118:163-170. [Google Scholar] [PubMed]

- 40.Zhang H, Zhang X, Ding L, Ma J, Kong Y. Characteristics of cyanobacterial biomass gasification in sub- and supercritical water. Energy Fuels. 2019;33:3239-3247. [Google Scholar] [PubMed]